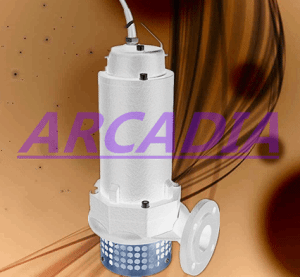

进口高温耐磨蚀潜水电泵美国阿卡迪亚品牌

进口高温耐磨蚀潜水电泵Product Description:

The upper and lower covers are respectively sealed with the upper and lower openings of the motor housing. The stator and rotor are connected in the motor housing. The stator is externally connected with the cable threaded on the upper end cover through the compression nut. The rotor is connected with the motor spindle. The upper end cover is locked and tightly connected to the water inlet chamber. The motor spindle is connected to one end of the coupling placed in the water inlet chamber through the upper end cover. The coupling is sleeved with a sand flinging ring. The water inlet of the water inlet chamber is equipped with a sewage screen, The water inlet chamber is locked and tightly connected with a guide vane body or two or more guide vanes connected in series in turn. The other end of the coupling is connected with the water pump spindle threaded in the guide vane body. The water pump spindle is provided with an impeller placed in the guide vane body, and the guide vane body of the last stage is externally connected with a water outlet pipe. The utility model has the advantages of compact structure, stability and firmness, high temperature resistance, corrosion resistance, sand prevention and safe use.

进口高温耐磨蚀潜水电泵characteristic:

Downhole pump is the most important power equipment in the whole thermal cycle, which is responsible for pumping high-temperature and high-pressure working fluid out of the production well and reinjection the cooled working fluid into the injection well. The downhole pump has been in the working environment of high temperature and high pressure for a long time, and the circulating working medium is the sand and stone brine with strong wear and corrosion. Therefore, it has high reliability requirements for the submersible pump used for the downhole pump, and its normal operation is very important for maintaining the working medium circulation and power generation efficiency. However, the working fluid passing through the downhole thermal reservoir contains a large number of fine rock particles and a variety of chemical substances. In addition, the downhole high temperature greater than 100 o C brings great challenges to the downhole circulating pump. The traditional multi-stage submersible deep well pump is used to pump clean water at normal temperature, and the internal water guide bearing is lubricated by clean water, which can not bear high-temperature sandy medium at all; The connection between the submersible motor and the multi-stage hydraulic components can not prevent impurities from entering the motor and bearing cavity

进口高温耐磨蚀潜水电泵Principle:

The upper and lower openings of the motor shell are sealed. The lower end cover is provided with a probe, and the upper end cover is provided with an oil-water probe. The motor shell is connected with the stator and the rotor. The cable package of the stator is externally connected with the cable threaded on the upper end cover through the compression nut. The line guard plate device separates the upper end cover and the cable package. The rotor is connected with the motor spindle. The upper end cover is locked and tightly connected to the water inlet chamber. The motor spindle is connected to one end of the coupling placed in the water inlet chamber through the upper end cover, The coupling is sleeved with a sand throwing ring, the water inlet of the water inlet chamber is provided with a sewage screen, the water inlet chamber is locked tightly connected and connected with two guide vane bodies connected in series in turn, the other end of the coupling is connected with one end of the main shaft of the water pump threaded in the guide vane body, the main shaft of the water pump is provided with an impeller placed in the guide vane body, the guide vane body of the last stage is externally connected with a water outlet pipe, and the middle and the other end of the main shaft of the water pump are connected through the shaft sleeve The copper sleeve is supported in the inner cavity of each self guide vane body, and the shaft end at the other end of the main shaft of the water pump is locked and fixed with a gasket.

(仅供参考)

| 配件编号 | 配件名称 | 规格 | 材质 | 单位 | 定性 | 价格(元) | 库存 | 供货期 |

|---|

采购单

采购单